What is Green Chemistry?

The U.S. Environmental Protection Agency (EPA) defines green chemistry as “the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances. Green chemistry applies across the life cycle of a chemical product, including its design, manufacture, use, and ultimate disposal.”

Rather than using fossil materials, many industries seek for new fields of chemistry to explore including sustainable chemistry. They then follow the concept of green chemistry which favors the use of natural resources or renewable raw materials as far as technology and economics allow it.

Green chemistry is a philosophy. It is broken down into 12 principles which aim to reduce the impact of chemistry on the planet and the end consumer.

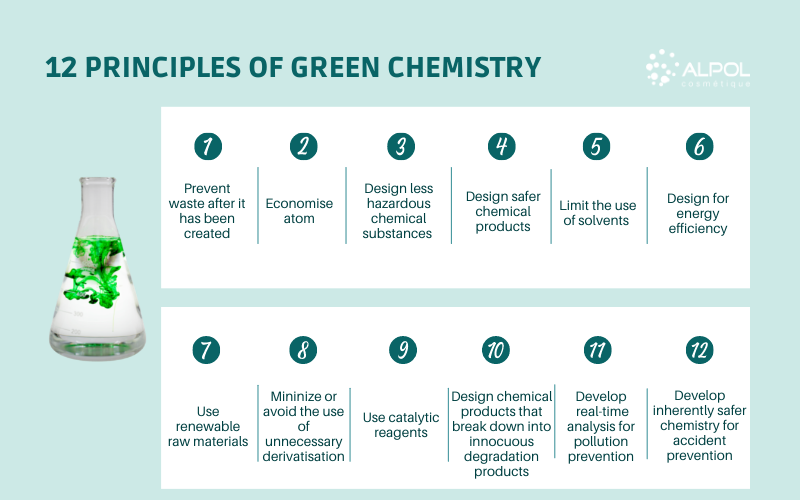

What are the 12 principles of green chemistry?

According to the Atomic Energy Commission (CEA), the concept of green chemistry appeared in the United States in the 1990s. It is based on the idea that “to eliminate pollution, banning polluting substances is an absolute prerequisite”.

In 1998, Paul Anastas and John Warner, researchers at the U.S. Environmental Protection Agency (EPA), developed 12 principles of green chemistry, which help to explain what the definition means in practice:

- Preventing waste rather than treating or cleaning up waste after it has been created;

- Economising atom to maximize the incorporation of all materials used in the process into the final product;

- Designing less hazardous chemical substances that possess little or no toxicity to human health and the environment;

- Designing safer chemical products to affect their desired function while minimizing their toxicity;

- Limiting the use of solvents and auxiliaries (e.g. separation agents, etc.);

- Designing for energy efficiency;

- Using renewable raw materials or feedstocks;

- Mininizing or avoiding the use of unnecessary derivatisation;

- Using catalytic reagents (as selective as possible) through minimizing waste by using catalytic reactions;

- Designing chemical products that break down into innocuous degradation products and do not persist in the environment;

- Developing real-time analysis for pollution prevention;

- Developing inherently safer chemistry for accident prevention.

How are the principles of green chemistry applied by manufacturers?

Manufacturing companies are not subject to produce in compliance with the principles of green chemistry. However, they can integrate one or more of these principles into their global business strategy whilst committing to corporate social responsibility.

Manufacturers showing awareness of sustainable chemistry seek to take into account one or more of these twelve principles when implementing a chemical synthesis or process within their production.

François JEROME, Director of Research at the CNRS, points out, “sustainable chemistry is not a science but a guide“.

In addition, a series of initiatives and strategies have been progressively deployed since 2019 under the concept of the European Green Deal, which includes the Chemicals Strategy for Sustainability (CSS) as well as the Sustainable Products Initiative (SPI). Their objective is to enable the marketing of safe and sustainable products.

These initiatives, which are still in the process of being rolled out, will eventually impact on industries, especially the chemical one, as well as manufactured products for consumers.

Although the general public tends to perceive green chemistry as “plant-based”, but it is not necessarily natural even though it contributes to reducing pollution.

How does ALPOL Cosmetique take into account the principles of green chemistry?

Concerned about its ecological impact, the French bespoke cosmetics manufacturer set up a responsible R&D charter to support customer satisfaction and sustain performance through the work of its laboratory and its teams, right from the design of each product development project.

It includes :

- Energy optimising through choosing less energy-intensive cosmetic formulation processes

- Selecting its raw material suppliers according to a specific grid

- Qualifying the origin of raw materials

- Optimising the use of raw materials to avoid rejects and waste

- Upcycling or recovering some of its waste

- Pay greater attention to the demands of sustainable chemistry thanks to the expertise of its regulatory department

- Increase the added value of its sustainable actions thanks to its control of the entire value chain, from the design of cosmetic formulations to the delivery of products.

Do you have an eco-designed cosmetic development project in line and you’re looking for a cosmetic manufacturer to support you with it?